Our organization aims to operating faithfully, serving to all of our consumers , and working in new technology and new machine continually for High Quality for Small Factory Use Maize Wheat Flour Milling Machine, We are glad that we are steadily growing with the active and long term support of our satisfied customers!

Our organization aims to operating faithfully, serving to all of our consumers , and working in new technology and new machine continually for China Wheat Flour Milling Machine and Wheat Flour Miller, Our company offers the full range from pre-sales to after-sales service, from product development to audit the use of maintenance, based on strong technical strength, superior product performance, reasonable prices and perfect service, we'll continue to develop, to offer the high-quality solutions and services, and promote lasting cooperation with our customers, common development and create a better future.

| Products variety | Maize fine flour |

| Maize germ | |

| Maize bran | |

The maize milling machine can produce different kind of maize meal,and maize flour,food for making Africa staple food.

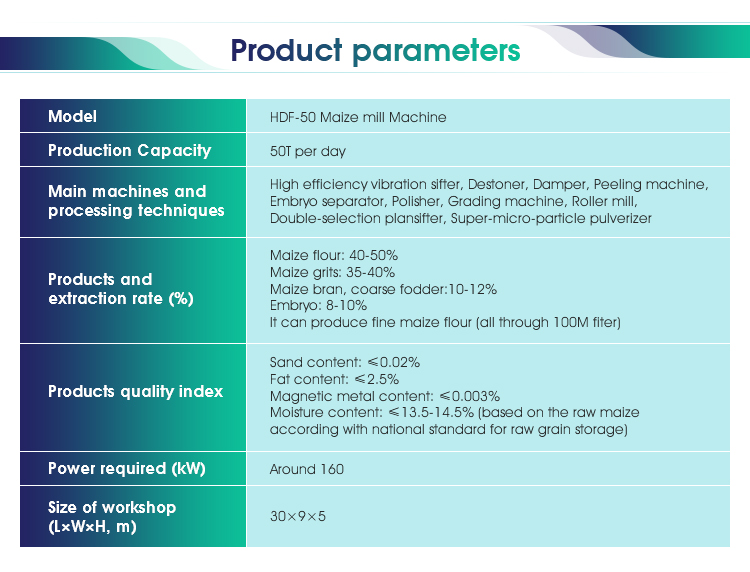

Products quality indexFeatures of Maize Grinding Machine:

1. Turnkey project of maize grinder machine.

2. Advanced technology support and customized design.

3. Thorough crafts and rational allocation.

4. Low power consumption.

5. Perfect after-sales service.

6. Two year guarantee.

This is the commercial maize flour milling processing machine,It include four-step: cleaning--maize degerminating--milling--maize meal packing

1. Cleaning system:when buying the maize,normally the maize is very dirty in Africa countries.So before processing, need to cleaning first.In the maize there is many kind of impurity,like stone,iron,rope,plastic etc. So according this we use maize drum sifter/maize cleaner/maize destoner etc machines to cleaning the maize

2. Degerminating system:After cleaning the maize, before degerminating,first need the moisture the maize and let the maize sleep in the moisture bin for 2-10 hours according the different request, then go to the maize degerminator, the degerminator can scrub the maize skin from maize kernel and dislodge the germ from its cavity with the minimum reduction in size of broken fragments

3. Milling system:The process of manufacturing the products involves three fundamental sub-processes. Firstly, physically detaches the three components of the maize kernel from each other with as little dilution or mixing as possible. Secondly, sorts and classifies the detached particles into specific groups and the last, sizes and reduces the particles to the required granularity. The three components are then recombined as necessary depending on the type of finished product required. The aim of the process then, is to detach the bran and germ from the maize kernels with a minimum disintegration of either the endosperm or the bran/ germ casing. The pure endosperm is then gradually reduced in size to form products of different granularity, ranging from the relatively large pieces of samp to the very Fine maize flour.

4. Packing system: Maize flour packaging machine can packing with different kind of bags,like 1kg/2kg/5kg/10kg/25kg/50kg

Packaging:

All machines are suitable for sea shipping